Lean for Social Innovation: More Food, Good Food, The Right Food

By Wiljeana Jackson Glover, Assistant Professor of Technology, Operations and Information Management at Babson College. This post is the first in our Fall 2015 series that explores how Toyota Production System (TPS) philosophies were applied at The Greater Boston Food Bank (GBFB) to support social innovation in MIS 3535 Lean for Social Innovation (held during Spring 2015). Posts include the opinions of thought leaders and Babson student perspectives.

Spring 2015 brought heavy snow, but great opportunities for continued partnership between The Greater Boston Food Bank, the Toyota Production System Support Center, and Babson. If you followed our collaboration last year, you know that we use the Toyota Production System approach to make improvements to the Marketplace area of GBFB, in efforts to support their quest to provide 50+ million pounds of food delivered.

This year, through MIS 3535: Lean for Social Innovation, we were able to address new challenges with social sector partners using experiential learning, i.e., “learning by doing” coursework, implementation of changes at the partner sites, and personal reflections.

Coursework:

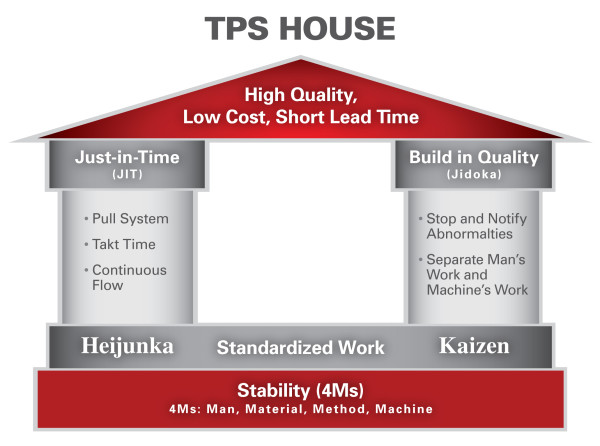

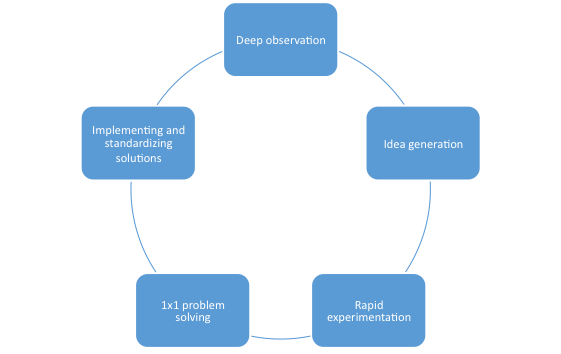

The course covers intermediate understanding of the Toyota Production System (TPS), including the philosophy, management’s role, technical tools, and what I’ve often called the “insulation” of the house of TPS: techniques for deep observation, idea generation, rapid experimentation, 1×1 problem solving, and implementing and standardizing solutions. Because we focus on organizations that provide economic and social value, we also discuss the implications of operational improvements in a social sector organization throughout the course. And because we are Babson, the course also covers lean startup, lean enterprise, and lean product, process, and service innovation.

The course also uses an adaptation of a simulation created by the MIT Lean Advancement Initiative Lean Academy. In the simulation, students participate in a group of outpatient clinics that are plagued with a legacy process, high process variation, and poor performance. The simulation gives them a practice field for learning and using lean tools within a consistent problem-solving process.

Implementing Changes:

Groups of 5 students were matched with GBFB as well as other social sector partners, including The Salvation Army-Waltham and the Rogers VA Hospital-Bedford. Students worked hard to build strong relationships with front-line workers and management in the organizations in order to deeply observe opportunities for improvement, justify the need for changes, and not just provide recommendations for change, but MAKE CHANGES!

Personal Reflection:

Perhaps the richest aspect of the course, students are responsible for writing four personal reflections of their time on site. It is those reflections that I am excited to share with you in this blog series. You will hear, from the students’ perspective, the challenges and triumphs of working with social sector partners to help them help the masses. This series will focus on the GBFB projects. We hope you enjoy hearing about their experiences and we look forward to your comments.