Lean for Social Innovation: Students and Toyota Activate Social Change

By Wiljeana Jackson Glover, Assistant Professor of Technology, Operations and Information Management at Babson College. This post is the first in a series that explores how Toyota Production System (TPS) principles were applied at the Greater Boston Food Bank (GBFB) to support social innovation. Posts include the opinions of thought leaders and Babson student perspectives.

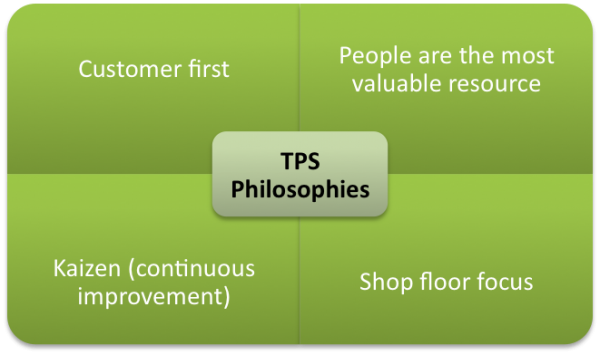

The Greater Boston Food Bank (GBFB) team has done incredible work to address hunger in Greater Boston for decades, delivering 47.8 million pounds of food to the area in 2013 and serving 540 hunger relief agencies and approximately 545,000 people annually. With a goal of 50 million pounds delivered in 2014 and always seeking new opportunities, Carol Tienken, the COO of GBFB, was excited to hear of an opportunity to work with Toyota and Babson College. Toyota has successfully worked with food banks and other non-profit organizations to share its knowledge (known as Toyota Production System or TPS) to help them find better ways of doing their day-to-day work and help more people in need.

Babson’s dedication to Entrepreneurial Thought and Action® and innovative learning added a new dimension to the collaboration. For example, the Management Consulting Field Experience connects Boston-area organizations with talented Babson students who work as consultants to address a current business challenge.

So in June 2013 an exciting idea was born: student teams would learn Toyota’s TPS integrated system through learning by doing; that is, they would not just read about TPS and make recommendations to GBFB, but would actually implement improvements at GBFB. The first targeted area for improvement chosen was GBFB Marketplace, an area where agencies can shop for perishable items quickly.

But this was the dream, not yet reality. In that moment we began to ask ourselves some tough questions. How would we do this? Could we actually implement improvements in one semester? What challenges would we face? What materials and support would we need? This is where our story begins.

Over the course of this blog series, former students, colleagues, and I will share our journey of using TPS to support social innovation at GBFB. We hope that it inspires you to try lean and Toyota techniques to create social value everywhere!